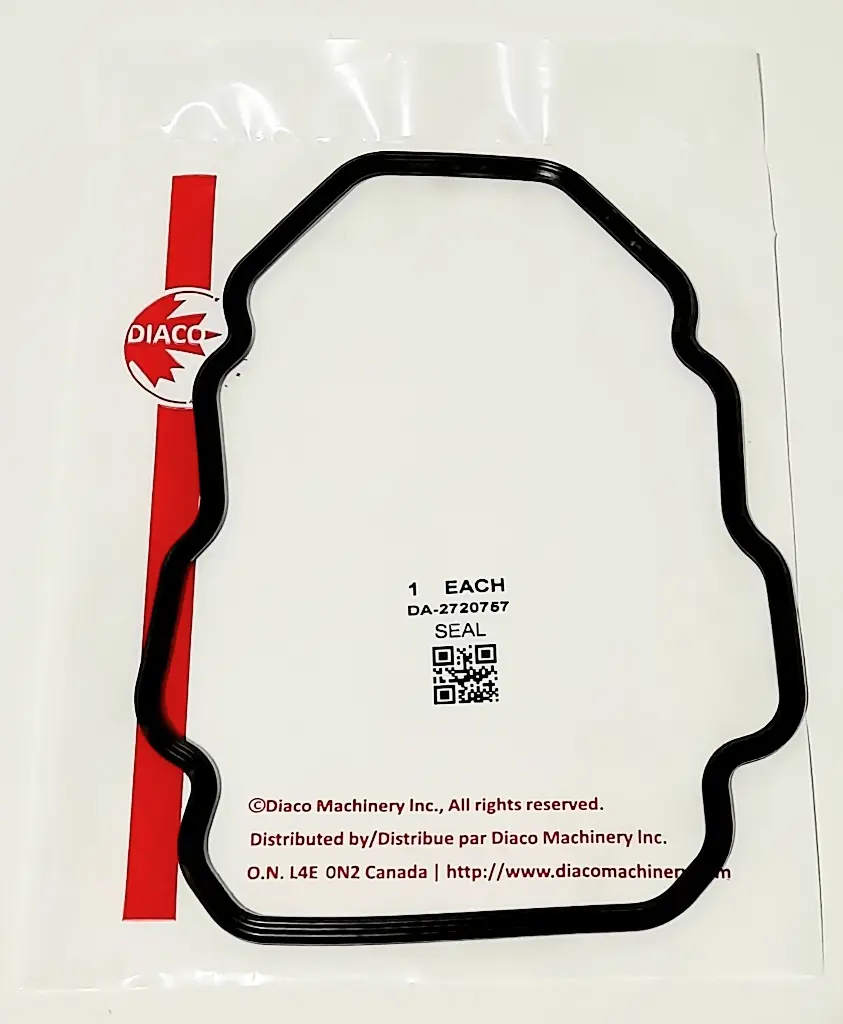

Descriptions

Press-in-Place seals are designed to maintain retention in the groove to improve assembly and prevent leakage and contamination. These are custom designs specific to the requirements of the application. Press-in-Place seals are made from materials that are matched to the fluids, temperatures and pressures found in engines and machines. The materials resist wear and extrusion, and provide superior resistance to seal compression set.

Attributes:

- Cross Section Height (in): 0.2

- Cross Section Width (in): 0.27

- Material: FKM,Fluoroelastomer (FKM) Rubber,Nitrile / NBR / HNBR / XNBR Rubber

- Material Description: FKM rubber is capable of service temperatures of -40 to 150C and is resistant to air, fuel (including bio-diesel), lubricants and oils. FKM rubber should not be used in applications that require resistance to water or coolant.

- Seal/O-Ring Type: PIP

Applications

Press-in-Place seals are used in many static joints throughout engines and machines. These are especially designed for inverted or vertical assemblies.

Compatible Models

GENERATOR

SR4 SR4B

GEN SET ENGINE

3512 3516 3508 G3516B

GENERATOR SET

G3516

MARINE ENGINE

3508 3516 3512

VEHICULAR ENGINE

3516 3512

INDUSTRIAL ENGINE

3512 3516 3508

GAS ENGINE

G3516